The Lambda100 system improves the quality of combustion through the analysis of the exausting smoke. The system controls the devices regulating combustion, keeping it within optimal set-point parameters, by managing both secondary post-combustion and primary combustion.

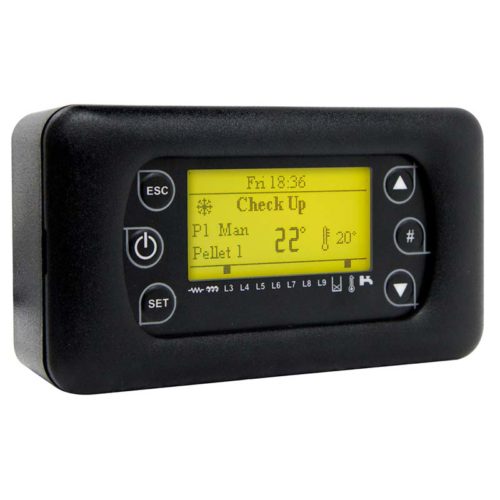

LAMBDA 100

Out of stock

Description

| Supply Voltage | 230/115 Vac 50/60 Hz |

| Lambda sensor input | Bosch LSU 4.9 |

| Communication interface | RS232 RS485 |

| Dimensions | Board 145×105 mm; Box 150x110x80 mm |

| Output to control | 05 On/Off 5A 250 Vac 03 Triac 1A 250 Vac |

| Low temperature measurement range | -40 ÷ 80/120/200 °C |

| High temperature measurement range | -40 ÷ 900/1250 °C |

| Additional modules | – Outputs 0 ÷ 10 Vdc – Iputs AUX – Double Encode |